S&R's experienced staff have the expertise to maximize volume yield and convert each log into the ideal products for the desired market segment.

At S&R Sawmills we work with our customers to create the best possible outcome for them. Our comprehensive processes include:

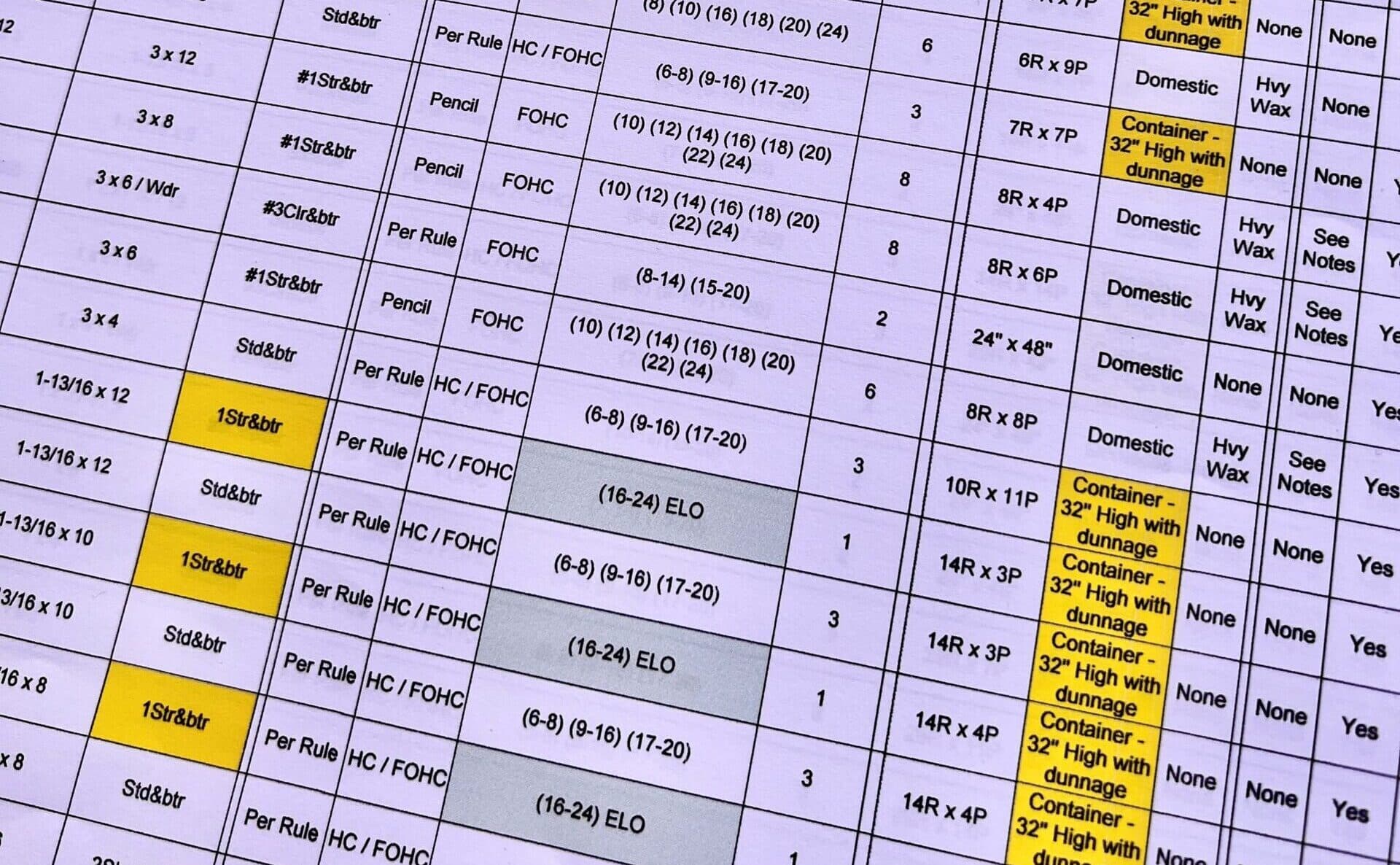

Our customer support begins with the cut plan and follows through to the final product. All stages of the log conversion process are closely monitored and any changes made are instantly communicated. Details matter and that’s why Quality, Size, Length, Sorts, are all carefully worked out. This determines how each log is cut and how the resulting lumber will be merchandized.

Our goal is to maximize the value of every log that comes to S&R. If you require log length monitoring to optimize timber output length, we can accommodate in-water log bucking.

Different grades of logs produce different grades of lumber. To ensure the best lumber recovery we carefully separate log grade zones for higher value return on timbers and lumber.

Real time production data allows us to actively track key products. Active monitoring ensures that the correct product quantities are produced, thereby optimizing your inventory.

At S&R we are able to offer very large sort capacities. Large sort capacities allow for more granular sorting which typically means lower downstream cost or higher product value for the customer.

Getting the most value possible from a log doesn’t happen by accident. Our experience, careful planning and state-of-the-art equipment all work together to ensure maximum returns for our customers.

Can't wait for us to get back to you?